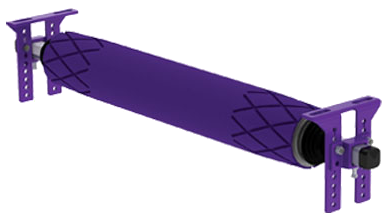

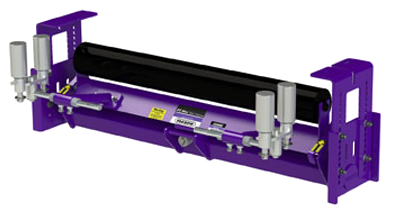

The PT Max™ is the only true high performance belt trainer on the market. Thanks to our unique “pivot and tilt” design, the unit reacts and compensates instantly to belt misalignment, ensuring that the belt stays away from the structure and the material stays on the belt. The PT Max™ delivers superior training action that makes it easy to keep even the most troublesome belts on track and on the job permanently.

Top side or return side belts. Heavy duty or medium duty operations. Wet or dry conditions. Belts mistracking to one side or both sides. Whatever the issue, the PT Max™ has the answer.

The FLEXCO Mineline® endorsement means it’s proven in heavy-tonnage applications that test the strength and durability of your conveyor system.

Features & Benefits

- For belts mistracking to one side or both sides

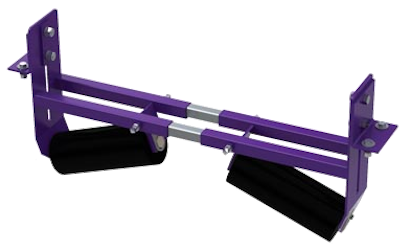

- Standard, heavy-duty, and super-duty models, and top- and return-side models

- Works with mechanically fastened and vulcanized belts

- Dual rollers that safeguard belt edges, reducing severe edge pressure and minimizing damage

- Easy to install and maintain – rollers can be replaced with standard on-site idler rollers

- Maximum Belt Tension:

-

- Standard Duty” 3000 PIW (525 N/mm)

- Heavy Duty: 6000 PIw (1050 N/mm)

- Super Heavy Duty: 10000 PIW (1750 N/mm)

- Belt speeds up to 1200 fpm (6 m/sec)

- Belt widths from 24″ to 84″ (600 to 2100 mm)

Installation