Choosing the proper mechanical belt fastening system is one of the most important steps in splicing a belt. Mechanical Fasteners combine strength and durability with fast, easy installation for a quality, long-term splicing option.

The Super Screw is a flexible rubber splice that screws directly onto the belt, with great accuracy and precision. It uses specifically designed self-drilling, self-tapping screws that preserve the belt integrity by spreading the carcass threads without cutting them.

This technology allows the Super-Screw to be installed regardless of the location or accessibility of the conveyor belt and regardless of weather conditions, all while significantly reducing downtime.

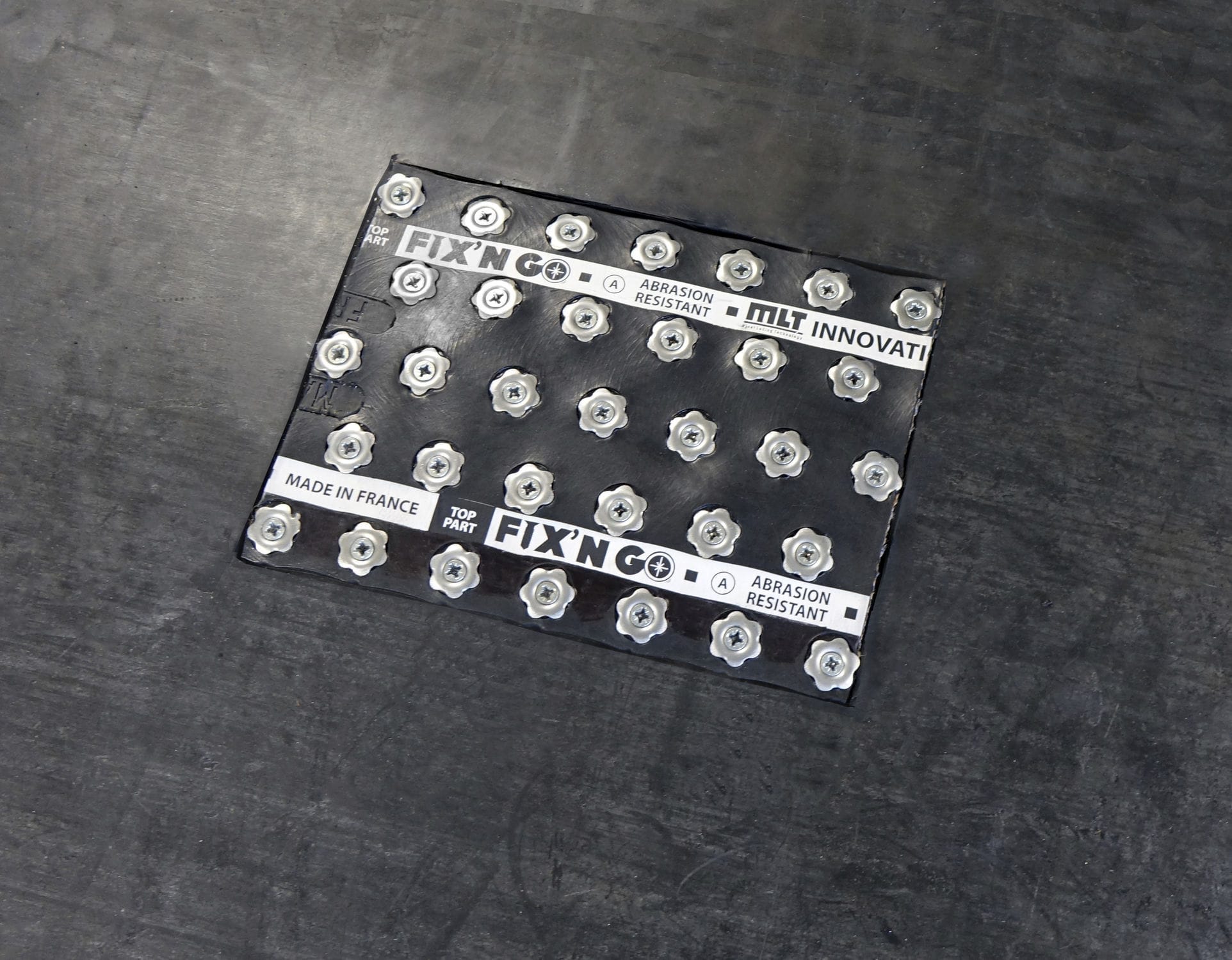

FIX’N GO PATCH®

Fix’N Go Patch® is an innovative and unique solution for repairing belt rips and tears. Thanks to the 50 mm3 rubber used, Fix’N Go Patch® has a higher abrasion resistance compound than most conveyor belts used today. All without impacting its flexibility, resistance to elongation and/or tensile strength. Repairing your belt with Fix’N Go Patch® results in a quick and permanent solution. No need to replace it.

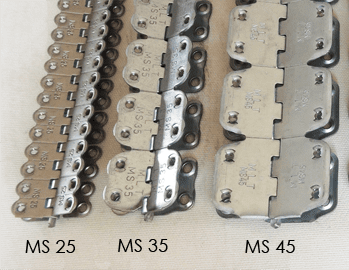

MS® FASTENER

The only screw-on fastener that is innovative and easy to install.

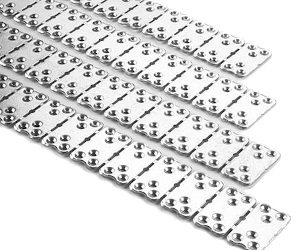

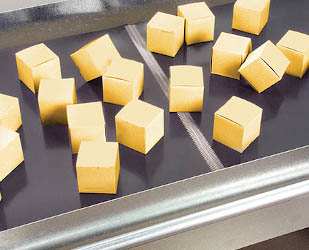

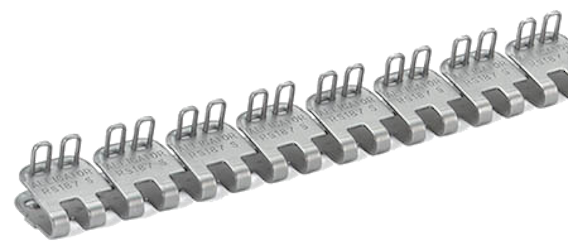

ALLIGATOR® Lacing Fastening System

The Alligator® Lacing Fastening System is ideal for easy, economical installation of a low profile belt splice. Available in continuous lengths, the system fits any belt width and provides uniform tension across the full belt width.

Why Lacing?

- Mechanical fastener rating up to 200 PIW (35 kN/m)

- Belts up to 1/2″ (13mm) thick

- Minimum pulley diameter from 1/14″ (25 mm-350 mm)

- Engineered to prevent pieces from working loose from the belt and into the product

- Removable hinge pin allows for easy cleaning and sanitation of belts

Teeth embed lengthwise in the belt, providing a strong, vice-like hold.

ALLIGATOR® Plastic Rivet Fastening System

The Alligator® Plastic Rivet Fastening System produces a non-scratching, non-magnetic, quiet mechanically-applied splice that can be easily dismantled for installation, cleaning and sanitation.

Why Plastic Rivet?

- Mechanical fastener rating from 40 to 65 PIW (7 to 11 kN/m)

- Belts from 1/32″ to 1/8″ (0.8 mm to 3.2 mm)

- Pulley diameters from 1/5″ to 3″ (38 mm to 75 mm)

- Beveled leading edges allow for smooth interface with conveyor components

- Produces a robust and abrasion-resistant splice

- UV-resistant black plastic for outdoor applications

- FDA-accepted white plastic

- Blue plastic for use with blue coloured belting used in the food industry

- One-piece, easy-to-clean design with rivets molded into the top plate

Spin-set installation through heat and friction provides a long-lasting splice.

FLEXCO® Rivet Solid Plate Fastening System

The Flexco® Rivet Solid Plate Fastening System is recommended for high-tension applications, with a staggered, multiple-point attachment for a long-lasting hold. Ideal for use with straight-warped belts because rivets separate the fibers instead of displacing the carcass.

Why Rivet Solid Plate?

- Mechanical fastener rating from 400 to 800 PIW (70 to 140 kN/m)

- Belts from 3/16″ to 15/16″ (5 mm to 24 mm) thick

- Pulley diameters from 14″ to 36″ (350 mm to 900 mm)

- Low-profile, Scalloped Edge® (design is conveyor component compatible)

- Wide, heavy-gauge plates promote long wear life, with a sift-free splice

- Rivet-attached for maximum resistance to pull out

Compatible with toughed belts.

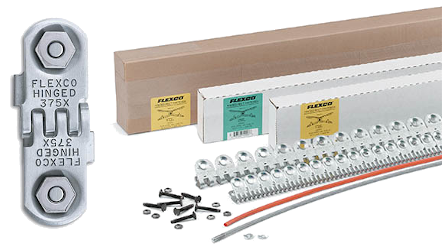

FLEXCO® Bolt Hinged Fastening System

The Flexco® Bolt Hinged Fastening System is ideal for belt conveyor applications subject to length adjustments because the joint can be separated easily by removing the hinge pin. A combination of penetration and compression delivers strength and reliability to belts operating over smaller pulleys.

Why Bolt Hinged?

- Mechanical fastener rating from 190 to 300 PIW (33-52 kN/m)

- Belts from 1/4: to 5/8I (6 mm to 16 mm) thick

- Pulley diameters from 6: to 9″ (150 mm to 225 mm)

- Hinged fastener with easy-to-install nuts and bolts

- Easy joint separation with pin removal

- Perfect for applications with belts operating over small pulleys

- Specially formed teeth penetrate belt carcass for added strength without damaging fibers

- Piloted bolts for quick and easy installation

- Curved templet aids in accurate placement of bolt holes and uniform tension across the full belt end

FLEXCO® Bolt Solid Plate Fastening System

The Flexco® Bolt Solid Plate Fastening System produces a strong, sift-free splice with superior holding ability thanks to a combination of top-and-bottom plate compression and high-tensile-strength bolts.

Why Bolt Solid Plate?

- Mechanical fastener rating from 150 to 560 PIW (30 to 100 kN/m)

- Belts from 3/16″ to 5/16″ (5 mm to 24 mm) thick

- Pulley diameters from 12″ to 48″ (300 mm to 1220 mm)

- Sift-free splice perfect for sand, gravel, crushed stone, and cement

- Specially formed teeth penetrate belt carcass without damaging fibers

- Piloted bolts for quick and easy installation

Available with rubber-covered top plates for increased impact protection and compatibility with conveyor components.

CLIPPER® Wire Hook Fastening System

The CLIPPER® Wire Hook Fastening System is designed with a variety of different wire diameters, leg and point lengths, metals, strip lengths, and styles to meet your individual application needs.

Why Wire Hooks?

- Mechanical fastener rating up to 200 PIW (35 kNm)

- Belts up to 25/64″ (10 mm) thick

- Minimum pulley diameter from 15/16″ to 7″ (24 mm to 175 mm)

- Available in two hook styles:

- Unibar® Fasteners – welded to a common bar to enhance installation safety and ease meshing of belt ends

- Carded Fasteners – individual hooks secured on carding paper for safe handling

- Low-profile design is conveyor component compatible

- Quiet operation when contacting pulley and other conveyor components

- Double-staggered grip pattern offer exceptional holding power, does not degrade the integrity of belt

- Quick, economical installation

ALLIGATOR® Staple Fastening System

The ALLIGATOR® Staple Fastening System is ideal for a wide variety of light- and medium-duty fastener applications. The system features on-piece fastener strips with pre-inserted staples that speed installation and keep downtime to a minimum.

Why Staple?

- Mechanical fastener rating up to 200 PIW (35 kN/m)

- Belts from 1/16″ to 1/4″ (1.5 mm to 6.4 mm) thick

- Pulley diameters from 2″ to 4″ (50 mm to 102 mm)

- Produces an abrasion-resistant splice

- Beveled edges and recessed staple pockets deliver a low-profile splice that is belt component compatible

Available in steel, stainless steel, MegAlloy®, and magnetic stainless.

FLEXCO® Rivet Hinged Fastening System

The FLEXCO® SR™ Rivet Hinged Fastening System is ideal for use on rubber-plied and PVC solid woven belting and for worn belts unfit for vulcanized splices, delivering performance and long life with easy installation.

Why Rivet Hinged?

- Mechanical fastener rating from 330 to 2000 PIW (60 to 350 kN/m)

- Belts from 1/8″ to 1″ after skiving

- Pulley diameters from 5″ to 42″ (125 to 150 mm)

- Low-profile, Scalloped Edge® design is conveyor component compatible

- Hinged splice – easily separated to remove, extend, or clean belts

- Rivet-attached for maximum resistance to pull out

Perfect for worn belting unfit for vulcanizing